The Surge in Utilization of System on Module in Designs Leveraging Adaptive System on Chip

As technology standards continue to evolve, product engineers are confronted with the daunting task of determining the system architecture and design methodology. In today’s world, where continuous innovation is a necessity, it’s crucial to incorporate scalability, flexibility, and modularity into the architecture of embedded designs. Product designers have several options at their disposal: they can opt for Commercial Off-The-Shelf Single-Board Computers, pursue a chip-down design, or utilize a System on Modules to construct a scalable product. Among these alternatives, the System on Module (SOM) approach has emerged as the favored design model, with the SOM market projected to hit USD 2.3 billion by 2025, growing at a Compound Annual Growth Rate (CAGR) of 11% from 2020 to 2026.

The ascent of Adaptive System on Chip

Adaptive System-on-Chips (SoCs) incorporate both the processor and FPGA architecture into a unified device, offering the required flexibility, scalability, and agility to accommodate expanding applications. The Zynq® UltraScale+™ MPSoC series delivers scalability for 64-bit processors, merging real-time control with soft and hard engines for graphics, video, waveform, and packet processing. These Adaptive SoCs supplement the decade-long presence of soft-core CPUs and other soft IP for constructing systems on FPGAs. Adaptive SoCs prove to be especially beneficial when a part of an algorithm necessitates high performance that can be executed in hardware using parallel, pipelined, or a mix of both techniques. Nonetheless, designing Adaptive SoCs can pose a somewhat more complex task for product designers.

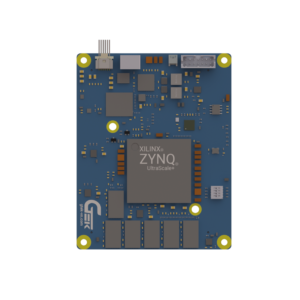

The Rationale Behind Using a System on Module Approach for Adaptive SoC-based Designs

In the realm of Adaptive System-on-Chip (SoC) based product design, the System on Module (SoM) methodology presents substantial benefits by alleviating numerous complexities inherent in the design cycle. The design of Adaptive SoCs involves intricate power circuit design, accompanied by related power sequencing and a higher power density per area.

The design of Adaptive SoCs encapsulates a series of intricate design challenges that demand highly skilled engineering:

- Handling of complex IO banks voltage

- Design of high-speed DDR memory

- Precise layout trace designs for serdes lines up to 58gb/s with necessary impedance

- Usage of special low loss PCB materials

- Restrictions on board form factor

- Management of high thermal conditions.

With the integration of the above designs and considerations into the System on Module, customers can now concentrate on their core competencies and product features, aiding them in reducing their time to market and development costs. iWave Systems, along with other system-on-module manufacturers, assume the responsibility of product longevity while managing the end of life for the multitude of components on the module.

During the design phase of the System on Module, the module undergoes an EMC compliance test and several rugged tests such as thermal cycling, aging, stress, etc. This robustness facilitates the easy and reliable adaptation of the system on modules to the product. The module vendors offer robust technical support in integrating modules into customer systems while providing hardware, FPGA, and software customization services. This enables customers to focus on their end applications and significantly save on product development costs.

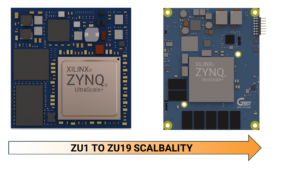

The SoM approach for the FPGA SoCs further enhances scalability for the end applications in terms of logic density, FPGA IOs, and the number of transceiver lanes. For instance, a well-architected carrier board design can accommodate system IO ports for multiple end products ranging from the Xilinx Zynq MPSoC UltraScale+ ZU4 with 192K logic cells to ZU19 with 1.1M logic cells. Moreover, the SoM approach facilitates the migration to new generation SoC solutions without altering the product’s mechanical architecture.

“System-on-Modules make Xilinx technology accessible to both current and non-traditional customers,” stated Chetan Khona, Xilinx director of Industrial, Vision, Healthcare & Sciences markets. “Particularly due to the global social distancing and work-from-home mandates, the task of bringing up new custom hardware has become even more challenging than usual, leading many new customers towards the pre-qualified SOM approach. We believe this is a trend that is here to stay.”

The System on Module (SOM) methodology for FPGA System-on-Chips (SoCs) further enhances scalability for end applications in terms of logic density, FPGA IOs, and the quantity of transceiver lanes. For instance, a well-architected carrier board design can accommodate system IO ports for a multitude of end products, ranging from the Xilinx Zynq MPSoC UltraScale+ ZU4 with 192K logic cells to the ZU19 with 1.1M logic cells. Additionally, the SOM approach facilitates the transition to new generation SoC solutions without necessitating changes to the product’s mechanical architecture.

“System-on-Modules have made Xilinx technology available to both existing and unconventional customers,” stated Chetan Khona, Xilinx’s director of Industrial, Vision, Healthcare & Sciences markets. “Particularly in light of the global social distancing and work-from-home directives, the task of introducing new custom hardware has become even more daunting than usual, leading many new customers to opt for the pre-qualified SOM approach. We are of the belief that this is a trend that will persist.”